The World's Best! GCL Technology's granular silicon in Hohhot Sets a New World Record in Carbon Footprint

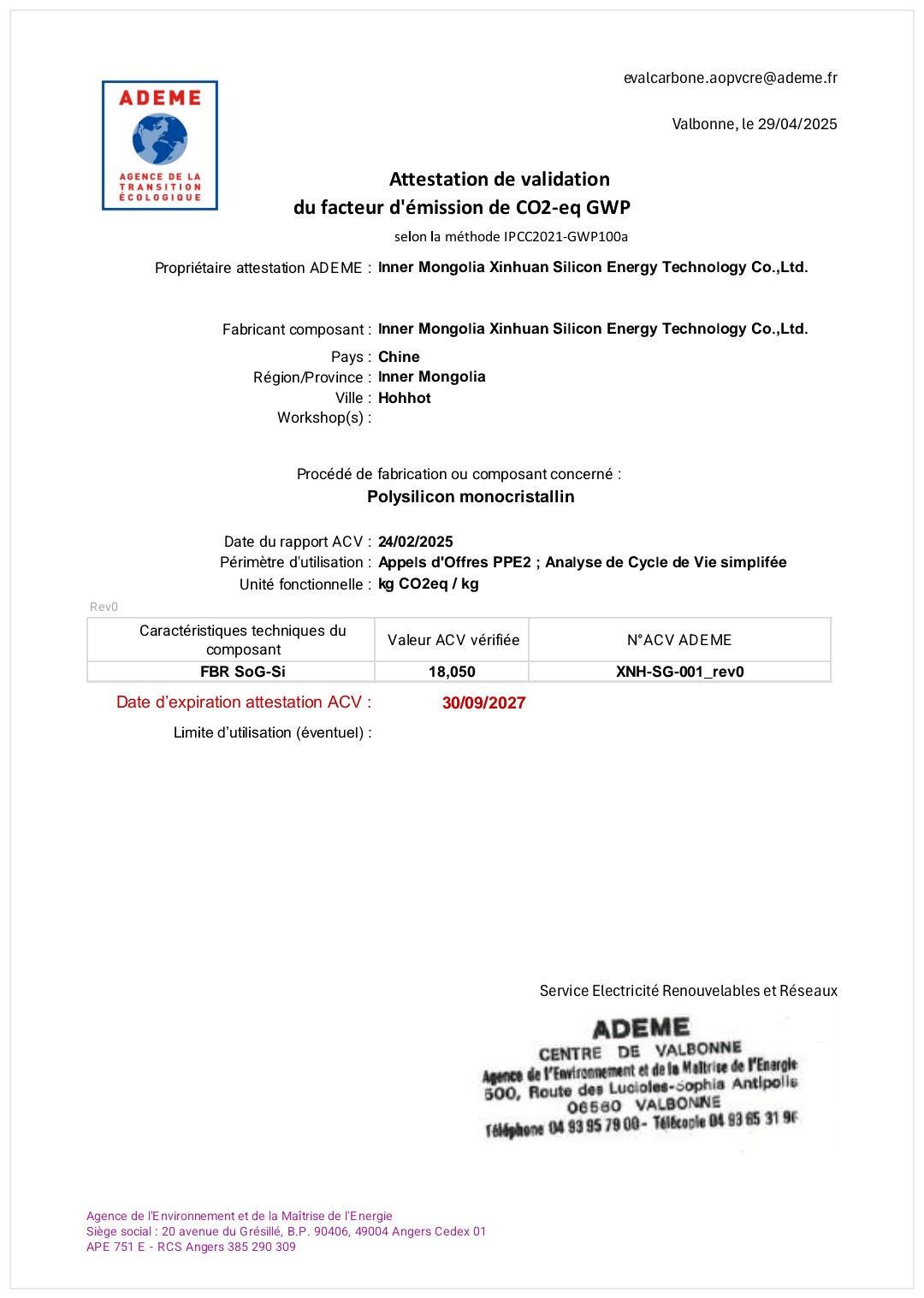

Recently, Inner Mongolia XinHuan Silicon Energy Technology Co., Ltd., under GCL Technology Holdings Limited, has received good news. Certified by the French Environment and Energy Management Agency (ADEME), the carbon footprint of its granular silicon products throughout their entire life cycle has been reduced to 18.050 kilograms of carbon dioxide equivalent per kilogram, far exceeding the industry average level and setting a new record for the lowest carbon footprint among global granular silicon production bases (excluding metallurgical silicon). This achievement not only demonstrates the practical results of GCL Technology under the "Three GCLs" strategy but also marks that it has set a new benchmark in the green transformation wave of the photovoltaic industry.

Breakthrough technological iterations create a low-carbon benchmark for the industry. As the core basic material in the photovoltaic industry chain, the carbon footprint level of granular silicon is directly related to the carbon neutrality process of the entire industry. Relying on the multi-base collaborative innovation advantages of GCL Technology, Inner Mongolia XinHuan has continuously made efforts in aspects such as process flow optimization, equipment and facility upgrades, energy and transportation planning, and intelligent manufacturing, driving continuous reductions in carbon emissions and continuous optimizations of the carbon footprint. This has not only strengthened the differentiated advantages of the products but also consolidated the enterprise's leading position in the industry, injecting strong impetus into the green transformation of the photovoltaic industry.

The international certification of low carbon provides a strong endorsement and enhances the competitiveness of products in the international market. Against the backdrop of the accelerated construction of the global carbon tariff system, carbon footprint certification has become an international yardstick for measuring the environmental value of products. The carbon footprint certification obtained by Inner Mongolia XinHuan's granular silicon this time not only provides strong support for downstream customers to reduce the carbon footprint of their products and enhance their competitiveness in the international market but also serves as a "green pass" for photovoltaic module exports to pass ESG reviews.

It is worth mentioning that the confirmation of this certification indicates that all granular silicon production bases under GCL Technology have obtained carbon footprint certifications from international authoritative institutions. Meanwhile, relying on the iterative upgrades of the GCL silane method process, the enterprise has continuously broken the industry's carbon footprint records, injecting green development genes into the photovoltaic industry from the source.

Green technology leads the "dual carbon" strategy, and GCL Technology bravely stands at the forefront as a pioneer in carbon reduction. With GCL Technology's continuous efforts in granular silicon low-carbon production technology, closed-loop production systems, and carbon management models, each production base has built a green intelligent manufacturing system covering the entire chain. In the future, GCL Technology will take the low-carbon gene of granular silicon as the foundation, go all out to build a zero-carbon production benchmark, drive the green transformation of the industry through innovation, and work with partners to embrace a new future of zero-carbon energy.